MS Life Steel – At a Glance

We are one of the India's steel exporters to other countries. Over the last 10 years, we have been at the forefront of science and cutting-edge technology.

MS Life on the Brink of Growth

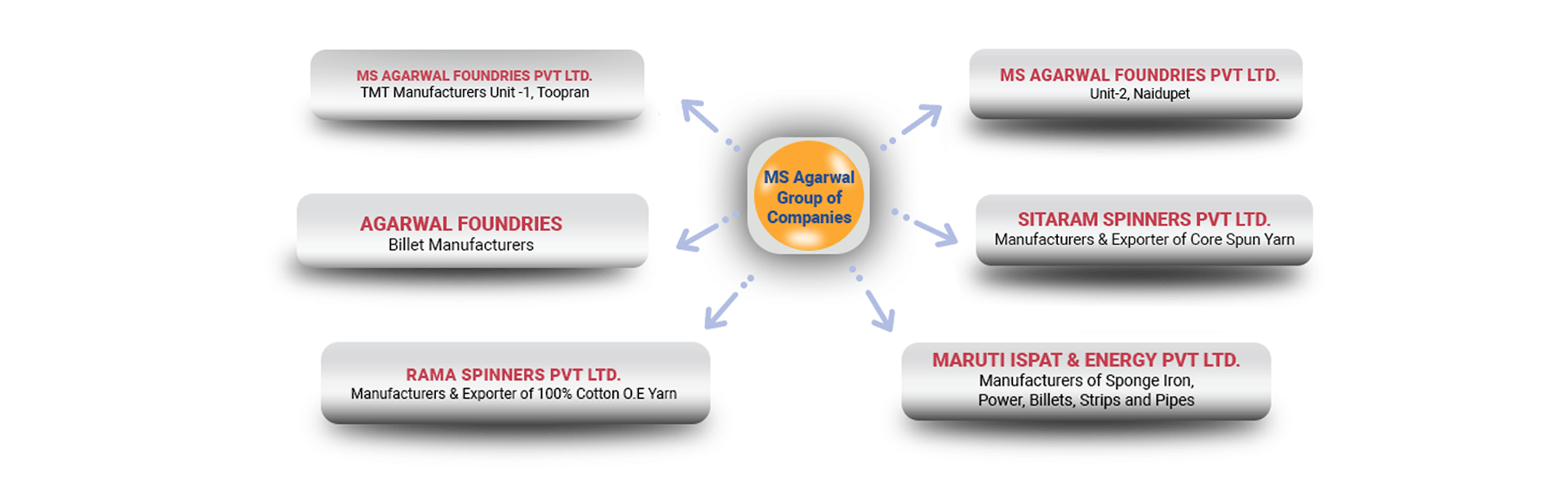

Starting with a single plant in 2005, we have now expanded into 3 units from Mines to Mills and are considered a leading manufacturer of value-added and high-grade steel products. With plants in Telangana and Andhra Pradesh we are major suppliers in the southern states of Telangana, Andhra Pradesh, Karnataka, Tamil Nadu and Kerala. MS Life has the capacity to produce 1.2 million tons per annum (MTPA).

Paving the way for a Better Tomorrow

By adapting to the fast paced changes we are maintaining the best-in-class standards. We aim to revolutionize steelmaking. Any visitor is marvelled at our engineering and the state-of-the-art facilities.

Bringing innovation in the construction industry since 2005

Established in 2005, the company has grown over the years to become an integrated steel plant having THREE factories spread across Andhra Pradesh and Telangana. The state-of-the-art manufacturing facilities are spread across more than 850 acres with a production capacity of 1,50,000 MTPA which is expected to reach 2,50,000 MTPS by 2020. With innovation at the core of its existence, it is the first steel company to manufacture 500, 550 and 600 grade steel bars in South India. Currently one of the fastest growing companies across South India, operating with over 750+ Channel Partners including 100+ exclusive channel partners, the company has, over the years, established goodwill for quality and innovation and has therefore been associated with projects of national importance like the Hyderabad International Airport, Bengaluru International Airport, Krishnapatnam Port, etc. As a leader in India’s steel industry, we believe it is our responsibility to improve and upgrade the quality of construction in the country.

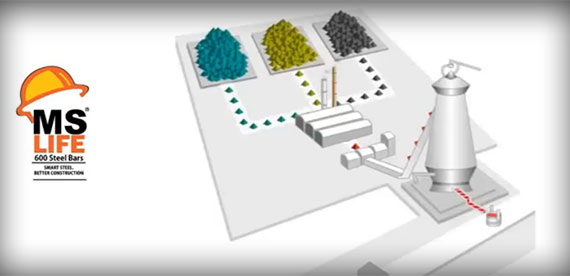

Integrated Steel Plant

Mines to Mills Integrated Steel Plant

The reason for our superior quality products and service can be attributed to the fact that we have a forward and backward, Mines to Mills integrated steel plant. This ensures that we have complete control over the entire process to achieve physical properties and chemical compositions to surpass BIS standards to manufacture merit quality steel. Having an integrated steel plant also ensures that we have complete control over quality, costs and timely delivery.

MS LIFE 600+ is produced through a combination of superior processes in our state-of-the-art integrated steel plant. The steel for MS LIFE 600+ is produced through primary steel making route, using iron ore. It is subsequently processed through the furnace and the virgin steel is refined to the fullest extent and continuously cast into billets. The resultant virgin steel is of superior quality containing no harmful ingredients and ensures the desired and consistent properties in the rebars. Cast billets are hot rolled in fully automated rolling mills equipped with controlled process monitoring devices to ensure uniform properties in each rebar. All our rolling mills are fully modernized with latest rolling technologies employing state-of-the-art tungsten carbide rolls in place of conventional steel rolls which ensure excellent dimensional tolerance and surface finish. Hence, the resultant steel has a fine finish, higher strength and superior quality.

The process of manufacturing TMT Steel Bars at MS Life starts from sourcing the best raw materials from the worlds’ best mines which is Iron Ore, Coal, and Dolomite. These raw material is then sent to KLIN unit where it is converted into sponge Iron. The material then becomes pliable and suitable to be shaped in any desired form in the DRI unit. Once it is out of the DRI unit, the material is then tested with chemical processes which begins within the continuous billet caster. The billets are then shaped into TMT Bars which are strong and resilient. The final testing ensures the quality output. The steel is also cut and bent to desired shape. Finally,the material is dispatched throughout India.

Awards & Recognition

It is our constant endeavor to push our limits and out perform our previous work and when we are appreciated for that, it only motivates us to work harder.